In Part 1 of our Ford’s Game-Changing Postwar Engines Series, we covered Ford’s first overhead valve V8s—the Y-Block, FE, and MEL Series. In Part 2, we took a deep dive into the small block Windsor V8 family. In our final story, we will explore Ford’s 385 Series big blocks—the 429 and 460.

The 1960s was a decade of transformation for Ford. The FE Series and MEL big block V8s introduced in the 1950s were becoming long in the tooth and it was time for fresh thinking. The result was Ford’s 385 Series 429 and 460 cubic inch big block V8s. The 385 name is based on the 460’s 3.850-inch stroke. The engines are also known as Lima V8s, named for the Lima, Ohio, plant which built them.

Ford designed these as luxury car engines making gobs of low-RPM torque to move heavy Thunderbirds, Galaxies, Montereys, and Lincolns down the road. What Ford product planners probably didn’t think about at the time was high performance—but drag racers did. They took the 429s and 460s and made them into powerhouses that could pump out 400 horsepower and some 500 lbs-ft. of torque.

Both the 429 and 460 have 4.362-inch cylinder bores. The main difference was the stroke—3.590 inches for the 429 and 3.850 inches for the 460. Following the rule of no substitute for cubic inches, you can put a 460 crankshaft in a 429 and no one will know it’s in there but you. The better bet is just go with a complete 460 as there way more of them out there than 429s.

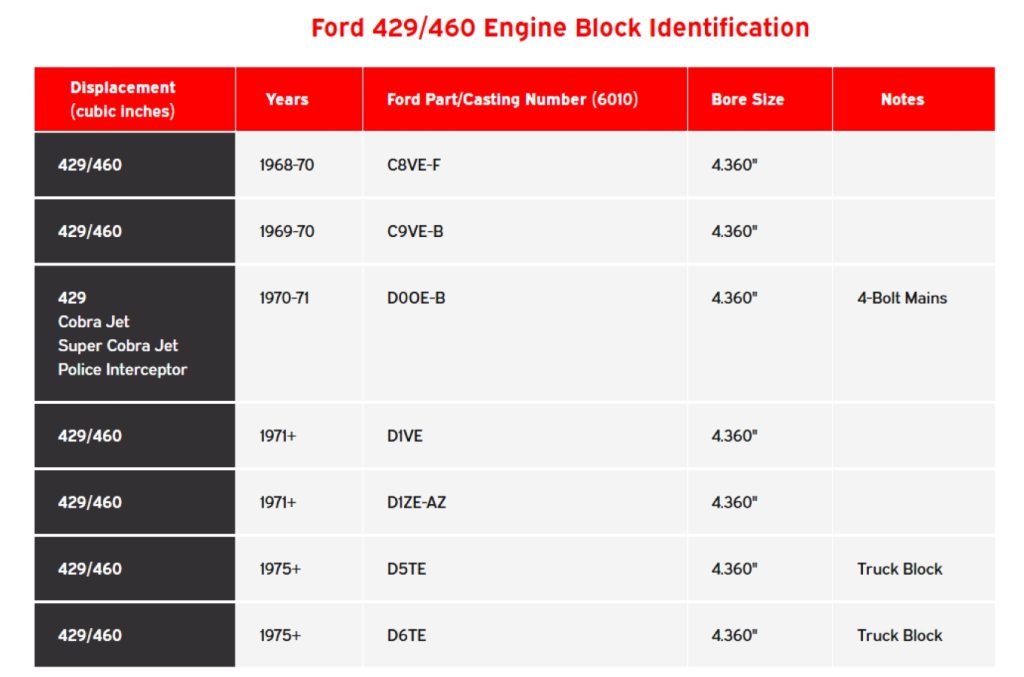

Blocks

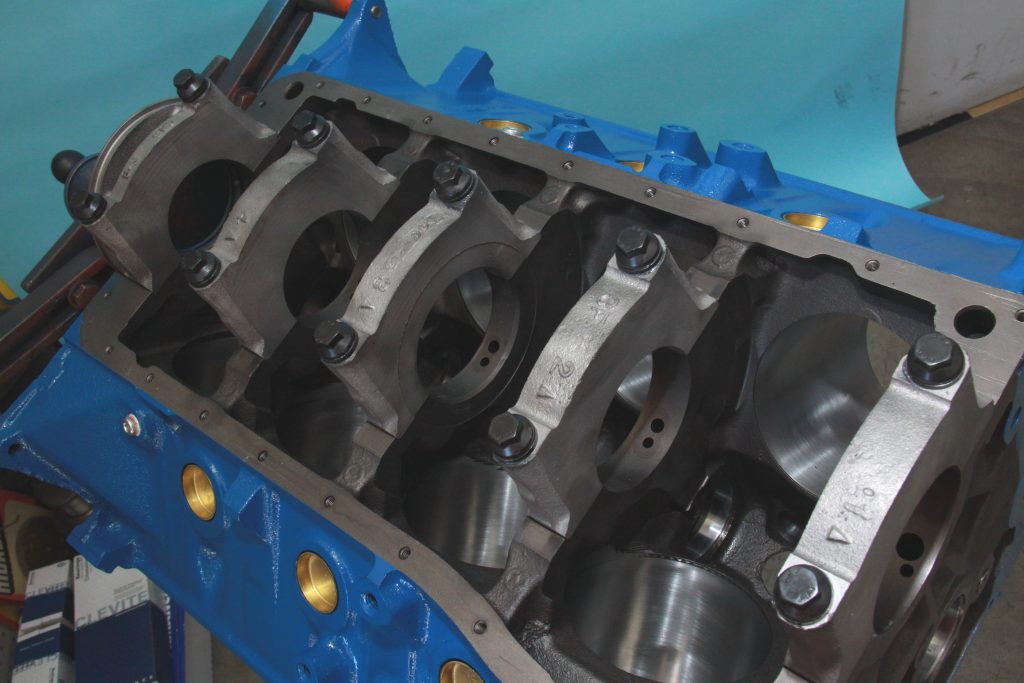

The 429/460 block is identifiable by the casting number—C8VE, D0VE, and D1VE-A. Most blocks had two-bolt main caps, and are plenty stout. All 1970-71 Super Cobra Jet blocks had four-bolt mains as did some 429 Police Interceptor blocks.

The later D5TE, D6TE, D7TE, D8TE, and D9TE truck blocks with thicker main webs are among the strongest and worthy of your consideration. The D9TE block has extended skirts (roughly .1875-inches deeper into the block) to improve piston stability at bottom dead center.

Crankshafts

All 429/460 engines were fitted with nodular iron crankshafts. The one exception is the Boss 429, which got a forged steel crankshaft. Those cranks have C9AE-A, C9AE-B, or C9AE-C forging numbers for NASCAR competition including street versions.

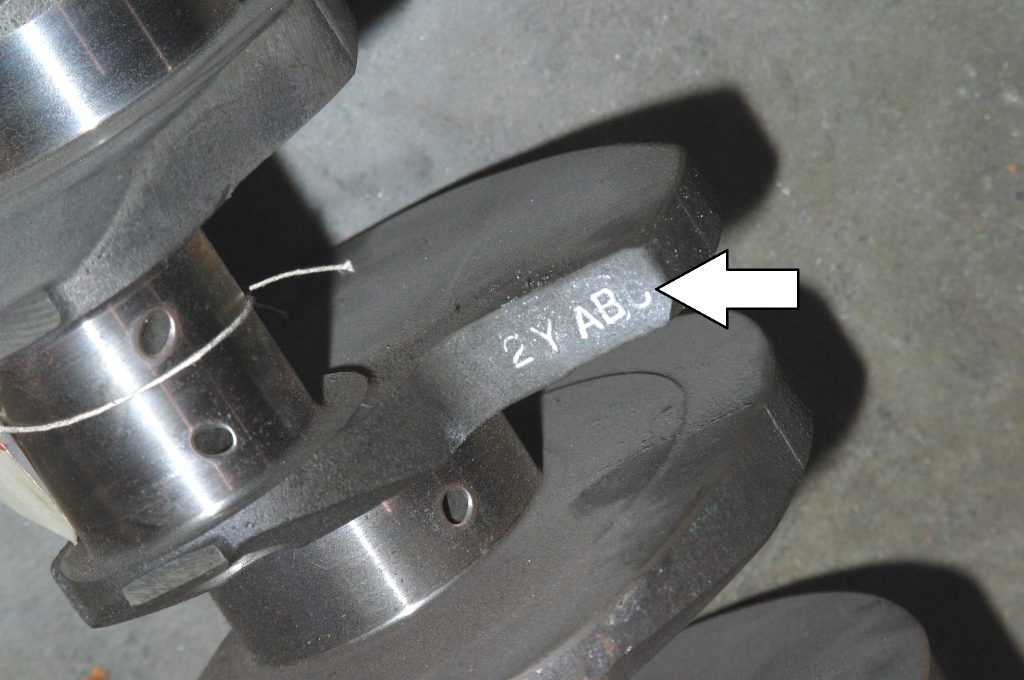

The 429 cranks are marked 4U and 4UA. The 460 cranks prior to 1979 are marked 2Y, 2YA, 2YAB, or 2YABC. After 1978 they are marked 3Y, though not all of them got the casting number.

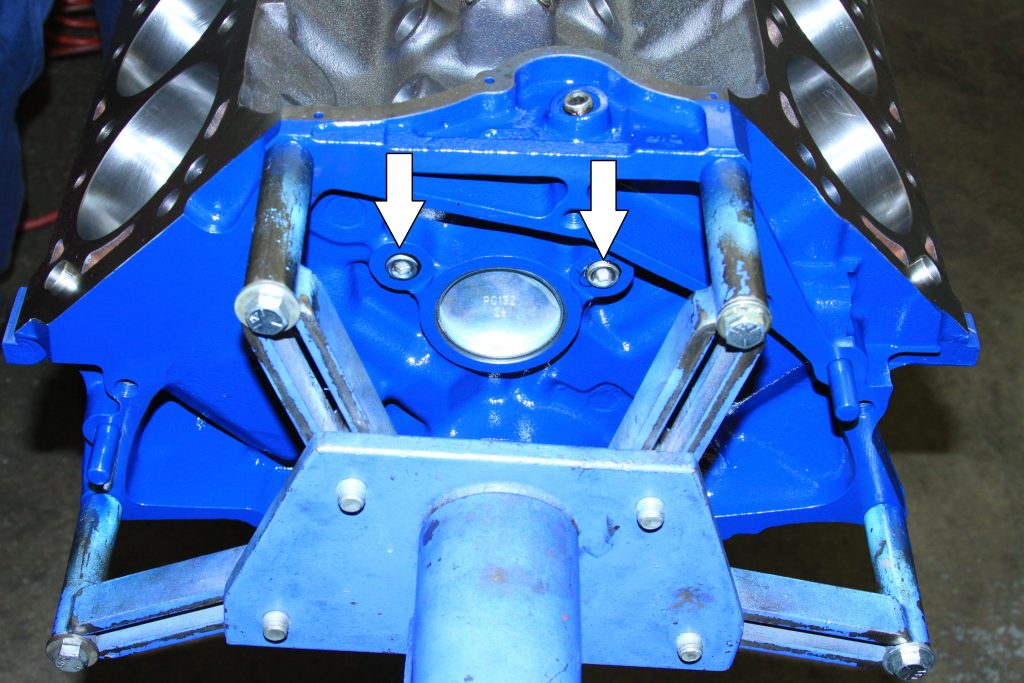

The 2Y and 4U crankshafts are internally balanced. The 3Y cranks externally balanced. This means 460 engines from 1979-96 are externally balanced.

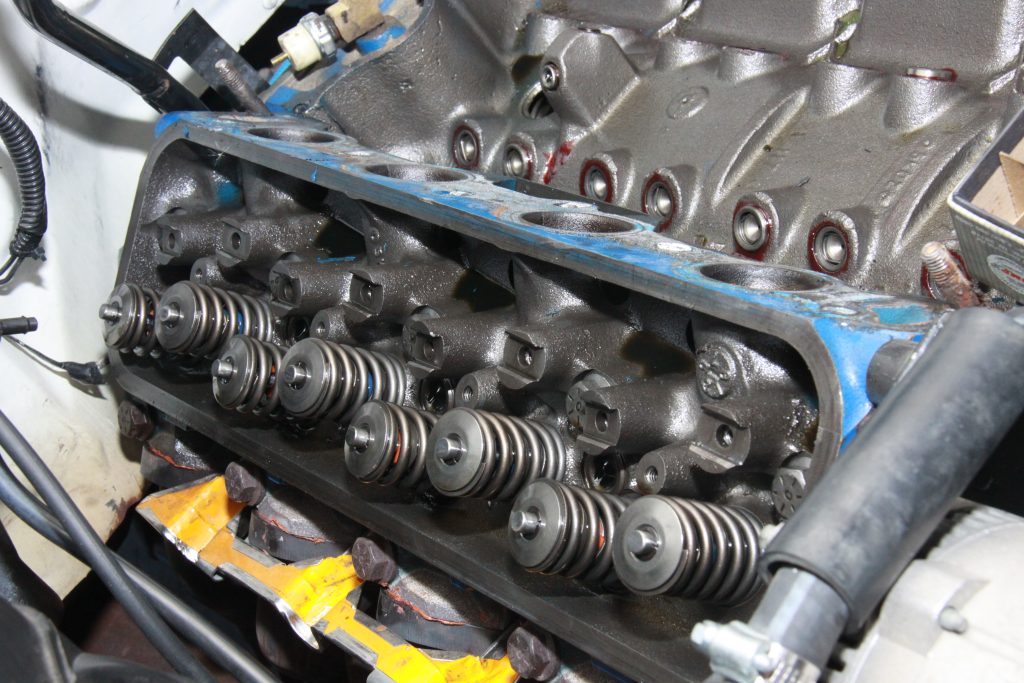

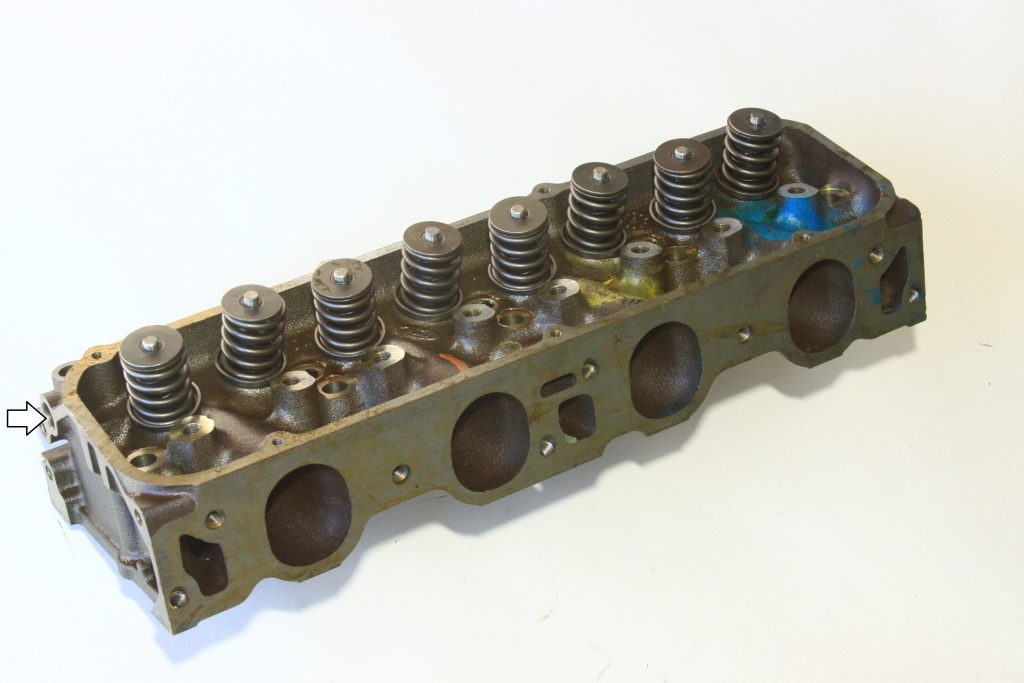

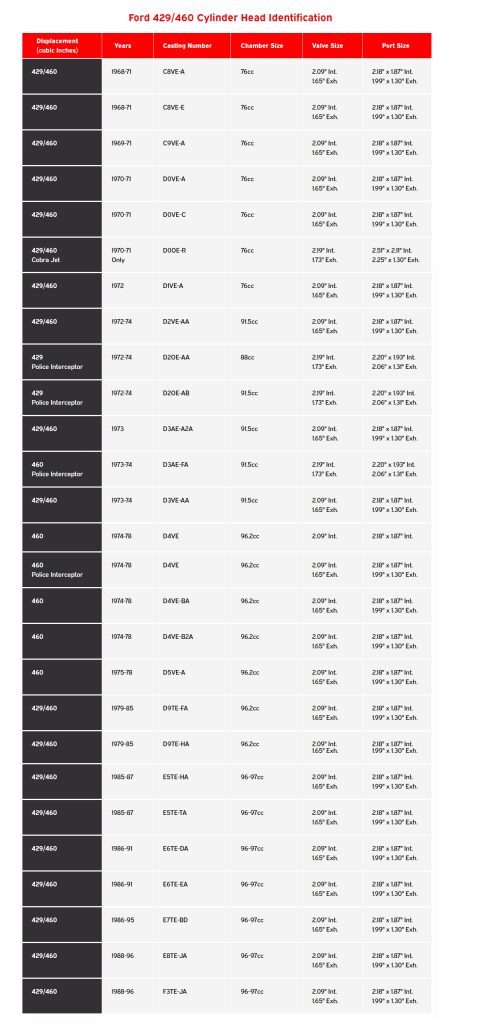

Cylinder Heads

Like the big-block Chevy and Ford’s 351 Cleveland, the 385 employed a canted-valve cylinder head layout with the intake and exhaust valves inclined four to five degrees and splayed nine degrees. There were just four basic castings over the engines’ 28-year production: standard 429/460, Cobra Jet, Police Interceptor, and Boss 429. A fuel injection version of the standard head came along late in the 1980s through the mid-1990s on truck 460s. Where the heads vary most is combustion chamber shape and size. Port sizes remained the same throughout the engine’s production life.

The 429/460 cylinder head delivers good flow and quench characteristics in all its forms. Port work can improve flow numbers. The heads to avoid are the Thermactor (smog pump) castings, which suffer from restrictive exhaust ports.

The best cast iron head for your money is the Police Interceptor, which is similar to the Cobra Jet head. There are three Police Interceptor castings—D2OE-AA, D2OE-AB, and D3AE-FA—all with 88-91cc combustion chambers. Port sizes are 2.200 x 1.930-inch intake and 2.060 x 1.310-inch exhaust. The heads make great low to mid-range torque, which you want for a street engine. Police Interceptor heads have hardened exhaust valve seats for use with unleaded fuel.

429 Cobra Jet and Super Cobra Jet

In 1970, Ford topped the 429 with large-port cylinder heads to create the Cobra Jet and Super Cobra Jet engines. The engines were around for just two model years (1970-71) and marked the high point of factory big block Ford performance.

The Cobra Jet had an 11.3:1 compression ratio and was rated at 370 horsepower and 450 lbs.-ft. of torque. It had a four-bolt block, cast aluminum pistons, and a hydraulic camshaft. The cylinder heads had smaller combustion chambers and larger valves than the standard 429. The Cobra Jet got a 700 CFM Rochester Quadrajet carburetor on a cast iron spread-bore manifold.

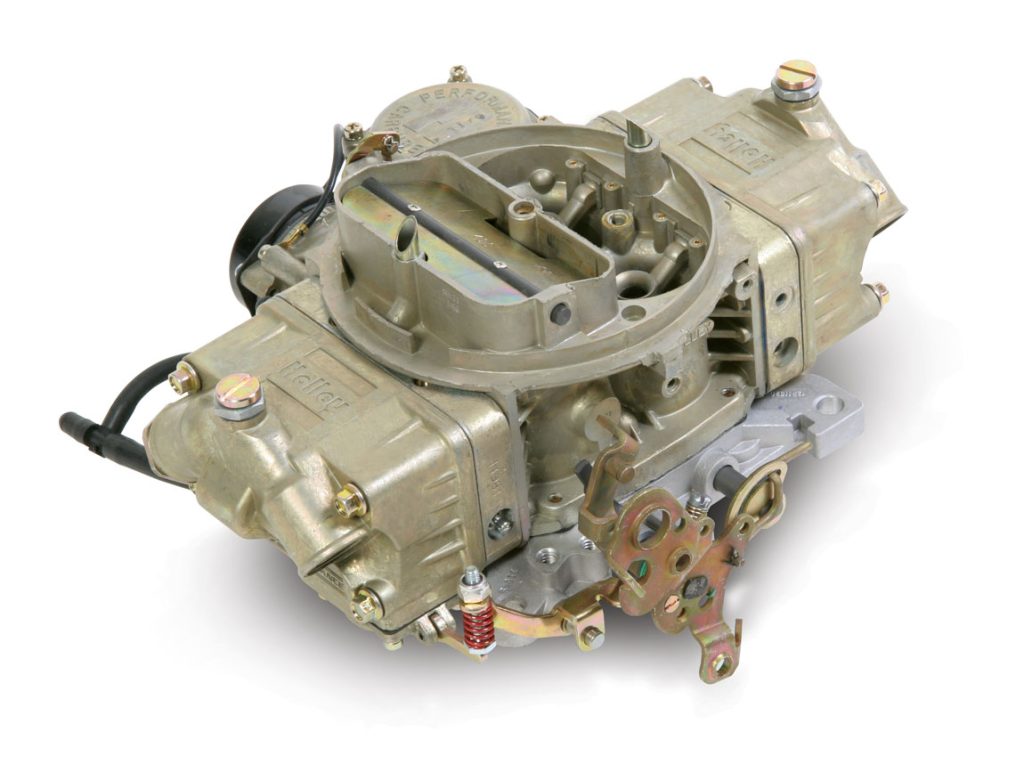

The Super Cobra Jet had 11.5:1 compression. It was rated at 375 horsepower and the same torque as the Cobra Jet, but made peak power 200 RPM higher (3,600 RPM vs. 3,400 RPM). You also got forged pistons, a mechanical camshaft, and adjustable rocker arms. The Super Cobra Jet had the 750 CFM Holley 4150 carburetor on a square-bore iron manifold.

Like GM and Chrysler, Ford underrated its performance engines by a considerable margin. Both engines actually made more than 400 gross horsepower.

BOSS 429

In the 1960s, Ford just couldn’t get a break from the powers that be at NASCAR. It needed a powerful engine to keep up with the Hemi Plymouths and Dodges. The 427 cubic inch SOHC “Cammer” FE-Series V8 would have given the Fords and Mercuries the oats they needed, but NASCAR promptly banned it.

Never one to give up, Ford topped the 429 cubic inch 385 Series big block with aluminum cylinder heads featuring crescent-shaped ‘semi-hemi’ combustion chambers, 2.38-/1.90-inch valves, and giant 2.36- x 2.36-inch intake ports. The aptly named Boss 429 was a NASCAR superspeedway beast that lived at 7,000-plus RPM.

To meet NASCAR homologation requirements, Ford had to produce a minimum of 500 street versions of vehicles with the Boss engine. Then-Ford President Semon E. “Bunkie” Knudsen decided to showcase the Boss 429 in the restyled Mustang. Although good for marketing it was an incredibly bad idea from a logistics and manufacturing standpoint. Ford built SportsRoof Mustangs at its Dearborn plant, then shipped them to Kar Kraft in Brighton, Michigan to be fitted with their powertrains. Just 1,358 Boss 429 Mustangs were built.

The Boss 429 street engine came in two versions. The S-code engine from 1969 had a hydraulic cam and NASCAR-grade (and heavy) rotating assembly. The T-code came along late in 1969. It had a solid-lifter camshaft and lighter bottom end components to reduce rotating mass and improve revs. Both had a too-small 735 CFM Holley carburetor, the Thermactor emissions system, and restrictive intake and exhaust manifolds required to fit the engine in the Mustang. Even so, Ford rated the Boss 429 at 375 horsepower and 450 lbs.-ft. of torque.

370 and 429 Truck

The 385 Series spawned two engines for use in medium duty trucks like wreckers and school busses. The 370 had the same stroke as the 429—3.590 inches—with a smaller 4.050-inch bore and a cast crankshaft. It was introduced in 1977 to replace the FE Series ‘Super Duty’ truck engines. The 370 was replaced with the 429 in 1992.

The 429 was introduced in 1979. It was based on the late 460 block, but had a short-stroke forged crank, shorter connecting rods with heavier pistons, and small-port cylinder heads—perfect for making tons of low-end torque. The 429 used a four-barrel carburetor until 1991 when Ford switched to EFI.

These are not good choices for building performance. The heavy rotating assemblies won’t allow the engines to rev much past 3,000 RPM. The front timing cover/front dress is completely different from the passenger car engines, as are the oil pans, pumps, and pickups. There are enough 460s out there that will make a much better base for a performance or light truck engines.

Build Your Own Big Block

There are parts galore to update or build an all-new 385 Series big block Ford from mild to wild. We’re talking camshafts and valvetrain, cylinder heads, rotating assemblies, carburetors and intakes, and even EFI. If you’d rather drop ready-to-run horsepower, Summit Racing has crate engines from ATK Performance and Ford Performance Parts that range from 515 horsepower and 460 cubic inches all the way up to 665 horsepower and 572 cubic inches.

Comments