The traditional bearing clearance standard for street and most performance V8 engines has been 0.001-inch of clearance for every one inch of crank journal diameter. Let’s take a 350 cubic inch small block as an example. Factory specs for main bearing journals is 2.450-inches and 2.100-inches for rod journals. Apply the 0.001-inch standard and main bearing clearance should be 0.0025-inch and 0.0021-inch for the rod bearings.

But say you’re building an engine and you find a main or rod bearing that is on tight side of the recommended oil clearance for your particular build. You might be the unwitting victim of something called stacked tolerances. This situation occurs when parts measure on the tight (or loose) side of their specified tolerance range. This is almost always due to inconsistencies in machining. When you assemble those parts together those tolerance deviations ‘stack up,’ causing issues with bearing clearances.

Here’s an example: You’re building an engine where main bearing clearances should be 0.0025-inch. The block’s main bearing bores are on the tight side of the tolerance range by 0.0003-inch and the crankshaft main journal diameters are 0.0002-inch too large. This tolerance stack up will cause close to 0.0005-inch of clearance loss—0.0020-inch instead of the recommended 0.0025-inch of bearing clearance. Following the accepted clearance standard, you have bearing clearances that are too tight.

If you have big clearance discrepancies on the majority of main or rod journals, you’ll either need to get the crankshaft machined to bring oil clearances back to spec or junk it and get a new crank.

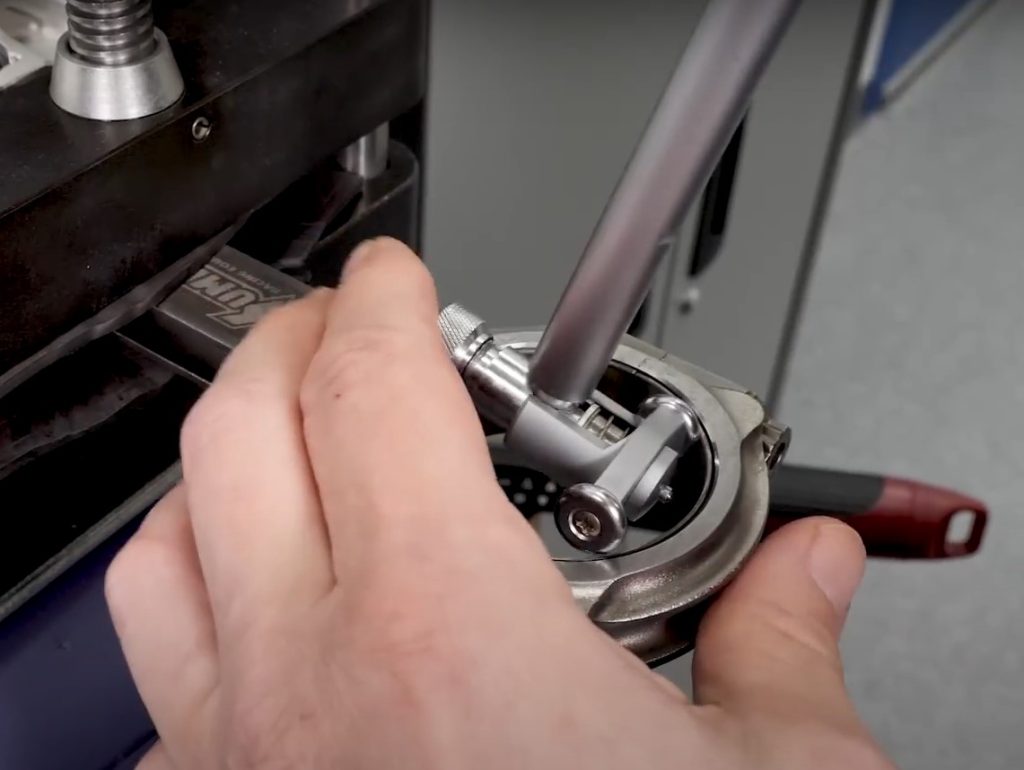

If the clearances aren’t excessive or don’t affect every journal, you can use a mix of standard and extra clearance bearings to set oil clearances at the desired specification. The process involves swapping bearing or bearing halves on the affected main or rod journal and rechecking the oil clearance.

Extra clearance bearings will have an X in the part number (STDX, HX). They add 0.001-inch of extra oil clearance if both halves are used. Using one standard bearing half and one extra clearance will provide 0.0005-inch of additional clearance. You only need extra clearance bearings for the journals that require them. As long as each journal has the required oil clearance, the bearings don’t have to match from one journal to the next. Just make sure to write down which journals have the extra clearance bearings.

When mixing and matching bearings, the standard half should be placed in the location that will see the most load. For the main bearings, this is the cap side. For the rods, it’s the upper side. It’s also a good idea to use bearings from the same manufacturer as they’re designed to work together.

A lot of people think that because standard and extra clearance bearings have different thicknesses, there will be a lip where the parting lines meet if you mix and match them. That is not the case. The difference in thickness is very small, just half a thousandth of an inch (.0005-inch). They are designed to provide slightly more clearance at the parting lines when torqued to spec, and almost all of the major load is directed towards the top or bottom of the bearing, not the parting lines. There really should be minimal, if any, contact between the crankshaft and the bearings at the parting lines.

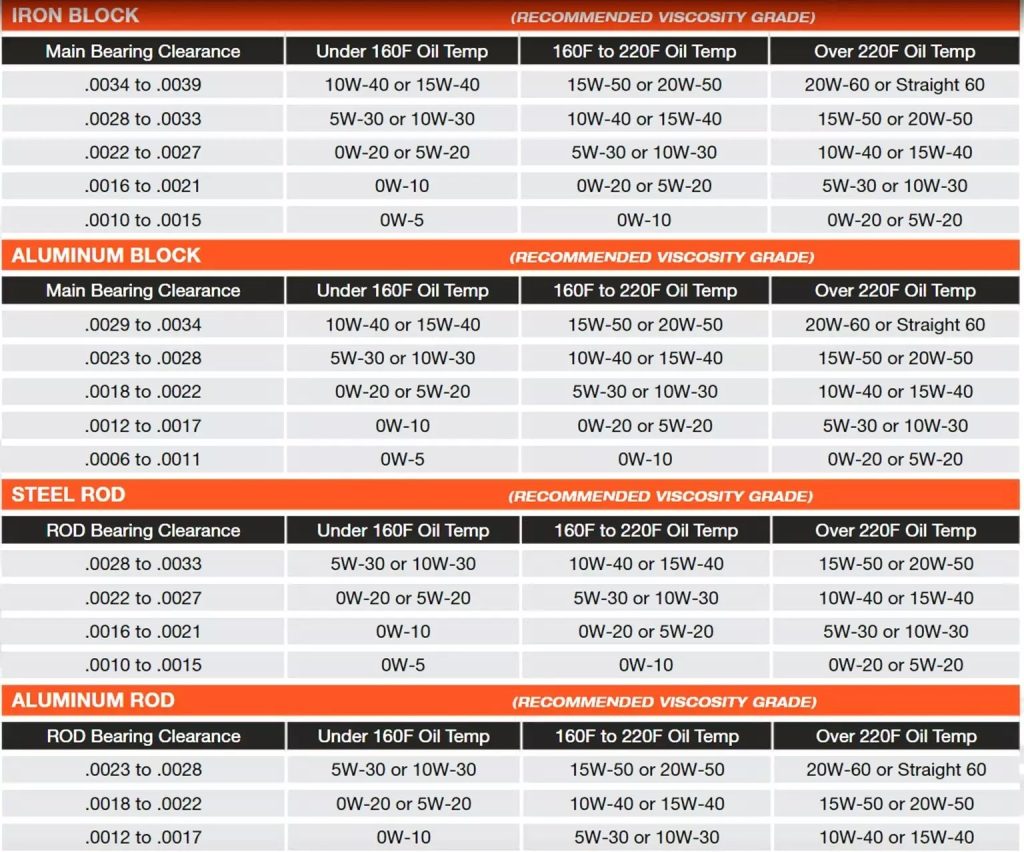

Extra clearance bearings are a great tool to solve a common problem. However, there’s a lot more to bearings than we can get to here—things like proper installation procedures; oil viscosity and temperature; and bearing materials all play a role. Fortunately, we have plenty of articles and videos that cover those topics and will make you the Keeper of All Bearing Knowledge:

Engine Building 101: How to Measure and Check Rod Bearing Clearance (Video)

Engine Building 101: How to Calculate and Measure Main Bearing Clearance (Video)

How to Properly Fit Engine Bearings

Ask Away! with Jeff Smith: A Quick Guide to Engine Bearings

Comments